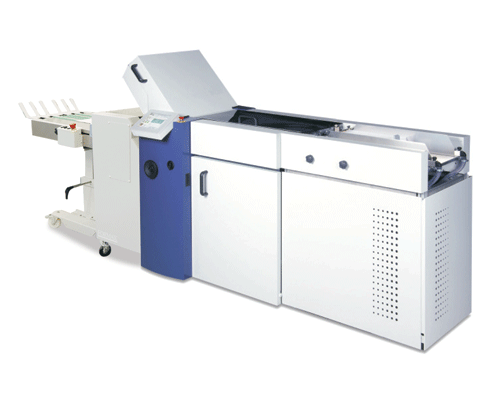

Formax AutoSeal® FD 2300 Series Production Pressure Sealers

Key Features

- Four in-feed options

- Speed: Up to 43,000/hr

- Color touchscreen control

- Program up to 200 jobs

- Unlimited duty cycle

- Automatic fold settings

- Heavy-duty rollers

Formax AutoSeal® 2300 Series Production Pressure Sealers:

The AutoSeal® 2300 Series High-End Pressure Sealers are designed to handle the highest volume jobs with ease and dependability, with speeds of up to 43,000 forms per hour. User-friendly features include the graphics-based color touchscreen control panel, and the ability to program up to 200 custom jobs. Fully automated settings include the feeder, alignment rails, fold plate stops, deflectors and fold rollers, and delivery rollers.

Five models are available in the 2300 Series which offer different infeed options:

- The FD 2300 utilizes an air-feed system with a capacity of up to 500 forms.

- The FD 2300-EX and FD 2300-EXT extended air-feed systems offer a capacity of up to 1,000 forms for the EX and up to 2,500 forms for the EXT.

- The FD 2350 utilizes a pile-feed system to reach a total capacity of up to 3,500 loaded forms.

- The FD 2380 works in-line with the Formax FD 676 Maxi Burster for processing continuous forms.

The Formax V-Stack36i Vertical Stacker is an available option which stacks up to 22” of processed forms, making them easier to unload for further handling.

All five models produce fast and accurate folds to deliver a secure and time-effective finished product ready for the mail. The 2300 Series clearly sets the new standard for high volume processing.

Specifications:

Hopper Capacity:

FD 2300: Up to 500 Sheets 24# (90gsm)

FD 2300-EX: Up to 1,000 Sheets 24# (90gsm) EXT: Up to 2,500 Sheets 24# (90gsm)

FD 2350: Up to 3,500 Sheets 24# (90gsm)*

FD 2380: Continuous Forms

Variable Speed:

Up to 43,000 sheets per hour – based on 11” Z-Fold (279mm)

Paper Size:

FD 2300/2350/2380: Up to 11.5” W x 25” L (292 W x 635 L mm)

FD 2300-EX/EXT: Up to 11.5” W x 14” L (292 W x 356 L mm)

Usage:

Production

Power:

208V, three phase, 20 Amp** (Special 3 Phase Power Required)

NEMA L21-20P plug included, NEMA L21-20R receptacle required

Dimensions:

Cut-sheet models: 152” L x 30” W x 56” H (386 L x 76 W x 142 H cm)

FD 2380: 167” L x 30” W x 56” H (425 L x 76 W x 142 H cm)

Weight:

Approx. 1,200 lbs (544 kg)

Delivery Requirements:

Customer-supplied fork lift is required for installation and setup

Certifications:

UL applied for

U.S. Patents 5,772,841, 5,865,925 & 5,968,308 Other Patents Pending

* Capacity of up to 3,500 non-windowed forms. Forms with a traditional patch window are better suited for the

FD 2300 and FD 2300-EX/EXT.

** Three phase power is required. NOTE: The FD 2300-EX/EXT model requires both a 3-phase 220V outlet and a second

separate 220V outlet (single phase) for the extended airfeed deck.

Specifications:

Hopper Capacity:

FD 2300: Up to 500 Sheets 24# (90gsm)

FD 2300-EX: Up to 1,000 Sheets 24# (90gsm) EXT: Up to 2,500 Sheets 24# (90gsm)

FD 2350: Up to 3,500 Sheets 24# (90gsm)*

FD 2380: Continuous Forms

Variable Speed:

Up to 43,000 sheets per hour – based on 11” Z-Fold (279mm)

Paper Size:

FD 2300/2350/2380: Up to 11.5” W x 25” L (292 W x 635 L mm)

FD 2300-EX/EXT: Up to 11.5” W x 14” L (292 W x 356 L mm)

Usage:

Production

Power:

208V, three phase, 20 Amp** (Special 3 Phase Power Required)

NEMA L21-20P plug included, NEMA L21-20R receptacle required

Dimensions:

Cut-sheet models: 152” L x 30” W x 56” H (386 L x 76 W x 142 H cm)

FD 2380: 167” L x 30” W x 56” H (425 L x 76 W x 142 H cm)

Weight:

Approx. 1,200 lbs (544 kg)

Delivery Requirements:

Customer-supplied fork lift is required for installation and setup

Certifications:

UL applied for

U.S. Patents 5,772,841, 5,865,925 & 5,968,308 Other Patents Pending

* Capacity of up to 3,500 non-windowed forms. Forms with a traditional patch window are better suited for the

FD 2300 and FD 2300-EX/EXT.

** Three phase power is required. NOTE: The FD 2300-EX/EXT model requires both a 3-phase 220V outlet and a second

separate 220V outlet (single phase) for the extended airfeed deck.

In Stock

In Stock